Tooling

Tooling Capabilities

Original Equipment Manufactures and Start Ups, require molds that function as planned and are ready to go, on time and budget.

In todays world, having a mold made, that doesn’t arrive on time or fails prematurely, isn’t an option.

Titan understands these constraints and will work closely with you, to make sure that the molds we build, meet your needs.

Unlike most plastics molding companies, we’re not going to try to re design your parts to make them moldable.

We respect your intelligence and make every effort to bring your designs to life, just as you intended them to be.

If we see a design issue that may negatively impact your part we will tell you upfront, rather than trying to fix the problem later. If you have a need for engineering support, we’re here to help.

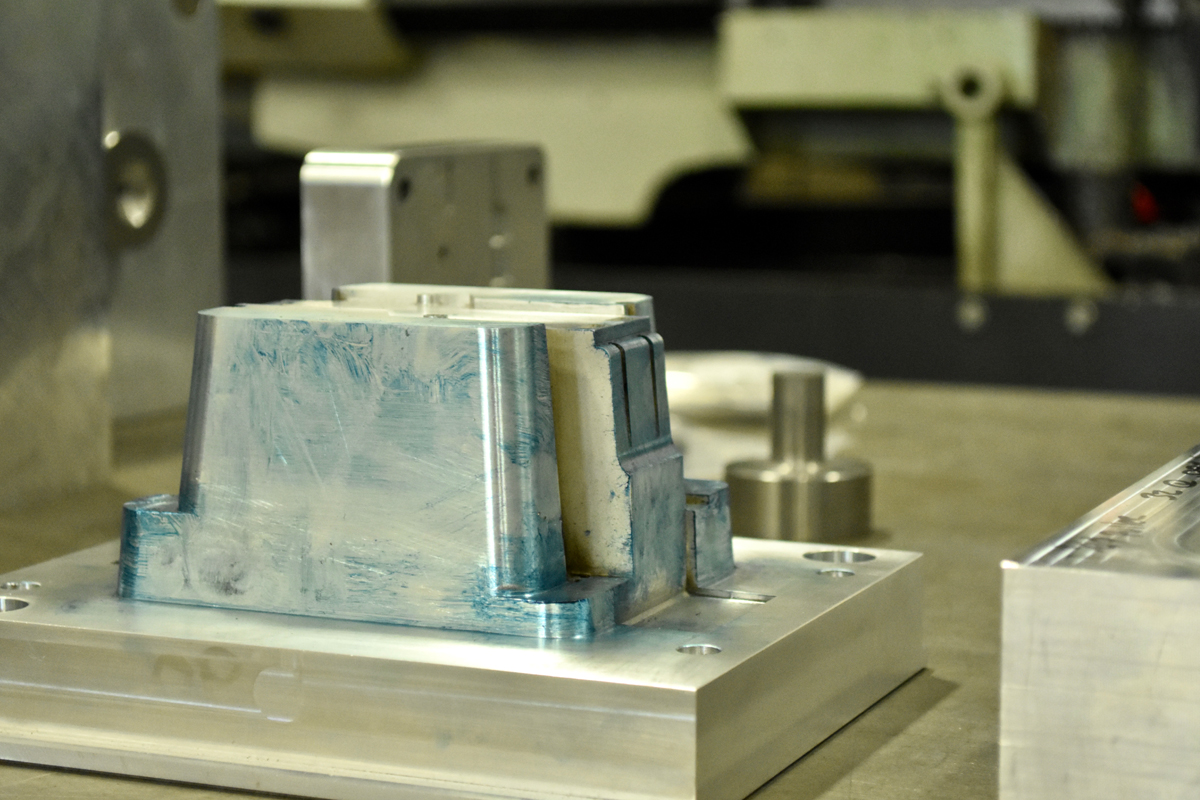

Titan is well versed in building molds for challenging parts, that may include, undercuts, holes, compound parting lines, snaps, threads and zero draft conditions.

Every mold we build starts with your CAD model being imported into our software.

For competitive reasons we can’t disclose what we use, but we can assure you it runs circles around the competition.

This software provides an end to end, absolutely seamless and fully integrated approach to mold design and manufacture. It’s this foundation that helps us do in minutes or hours, that takes days at the competition.

We can often design, and be CNC machining moderately simple molds, very quickly after receiving a purchase order.

Even complex highly detailed molds are designed quickly and accurately. Prior to finalizing any design, we will discuss ejector pin placement, gating, cosmetic and functional requirements with you.

To cut costs and reduce delivery time even further we can utilize one of 2 Master Unit Die sets. A 6.5x 8 inch and a 12×20 inch base.

When MUD sets aren’t the answer, we will purchase mold bases and components from leading suppliers like PCS, DMS, Progressive, DME and Hasco.

We have extensive experience machining and using high performance 7000 series Aluminum alloys as well as most tool steels including, P20, 420SS and H13.

Every mold that Titan manufactures meets or exceeds the required number of shots.

And, each one is constructed to meet SPI (Society of Plastics Industry) mold classification standards.

We’re capable of working in imperial (inches) or metric dimensions. Every mold that Titan manufactures meets or exceeds the required number of shots.